07-12-2008, 09:23 PM

07-12-2008, 09:23 PM

|

#2

|

|

AEM EMS

Join Date: Jul 2006

Location: UK

Posts: 891

|

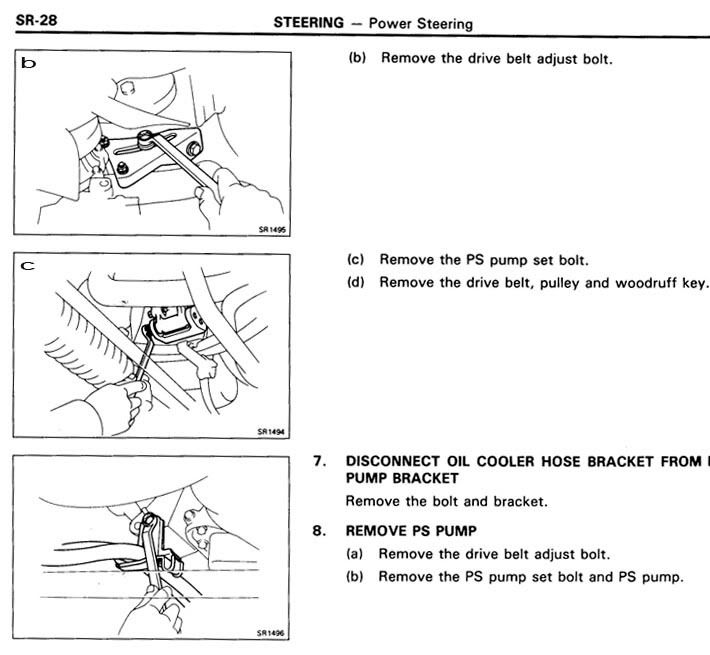

Strange Toyota didnít think of fitting a fine adjuster like the one on the alternator. The problem is, when you tighten up the adjuster bolt the pump moves towards the engine and loosens the belt. The only way is to put a pry bar between the pump and the front part of the engine to hold the pump in position. If the belt is to loose it will eventually try to run off the pulley, you can see evidence of this if the belt has a slit down the middle where the groves in the pulley have cut into the belt. Too tight and you run the risk of wearing out the pump bearing. You need only loosen two bolts, the adjuster bolt that you can clearly see looking down from the top of the engine bay and the pivot bolt (set bolt) which is underneath. As a guide I always adjust mine slightly on the tight side. The instructions below are for removal, you only need to loosen the bolts in fig b & c.

|

|

|